ClimOptic

ClimOptic

- New climate-efficient fertiliser for organic plant production

There is a great need to reduce climate gas emissions from agriculture as part of the global goal of keeping man-made climate changes below 2 ° C. This requires both reduction of climate gas such as N2O from the field and increased carbon storage in the soil.

The climate profile from organic crops can be increased in two ways; either by reducing emissions per cultivated area or by increasing the yields. An effective reduction requires both ways to be exploited.

Research has shown that yields can be increased through better fertilisation, especially through organic fertilisers with increased nitrogen utilization. Other research has shown that the carbon content of the soil is increased primarily through increased supply of plant residues in crops and after crops, where, however, there is an interaction with high emissions of Nitrogen oxide from plant residues in the soil.

Purpose of the project

The purpose of the Organic RDD 4-project ClimOptic is to develop, document and demonstrate optimised organic slurry applied in interaction with changes in crop rotation and slurry management for more climate efficient organic plant production.

The project will specifically develop two new types of slurry based on bio-degassed manure and plant residues: 1) A liquid sulphate slurry plentiful in ammonium and sulphur, and 2) a dry pelletized phosphorus organic slurry. These fertilisers are expected to be utilised significantly more targeted in organic production than current slurry, with lower Nitrogen oxide emissions and increased carbon storage, while increasing yields.

ClimOptic is focusing on farms with poultry and pigs or pure plant production, where livestock manure and plant residues are converted into biogas plants in order to achieve high utilization of nutrients and minimize greenhouse gas emissions.

A number of methods are being tested to post-treat degassed biomass to produce organic fertilisers that can be better assigned to the crops at times when the plants best utilize the nutrients.

The finishing is done at the biogas plant using mechanical and biological methods that are compatible with the ecological principles.

The subsequent processing takes place at the biogas facility using mechanical and biological methods that are compatible with the organic principles.

The project is expected to result in a reduction of greenhouse gas emissions from organic farming of 97,200 tonnes of CO2 eq. The project is expected to provide the basis for increased yields of DKK 132 million and sales of climate-optimised fertilisers to a value of DKK 13 million annually.

Project period: 2019-2022

Results and recommendations

Biodigested fertiliser provides lower climate impact and higher yields

The use of organic fertilisers can lead to high greenhouse gas emissions, and in combination with the lower yields in organic farming, this results in relatively high emissions per produced unit.

The ClimOptic project has demonstrated that it is technically possible to post-process digested biomass based on livestock manure and plant residues turning it into fertilisers with high nitrogen efficiency and low climate impact. This could potentially foster increased transition to organic farming, as farmers would have access to more effective fertilisers that may result in higher yields.

Significant reductions in the carbon footprint (per kg of grain) can be achieved by using a bio-digested fertiliser, and emissions can be further reduced through subsequent separation. However, this requires that emissions from the solid fibre fraction can be avoided, for instance by drying the fibre fraction. The reduction in greenhouse gas emissions is mainly due to a smaller loss of methane during the storage of unprocessed manure, which can be significantly reduced by processing in biogas plants. Additionally, the carbon footprint is reduced if the biogas replaces the use of fossil energy sources.

The liquid fraction of digested fertiliser can be used in biofilters

The project has shown that it is possible to use a recycled liquid fraction of digested fertiliser as input in biofilters, which are used in some biogas plants for sulphur cleaning of biogas. This can replace relatively large amounts of clean water and the mineral nutrients that are typically used in biofilters today. This results in an acidic liquid rich in sulphur, which can also be used to capture ammonia, potentially leading to a higher concentration of ammonium-N.

High fertiliser value of liquid fertiliser fraction

The project demonstrated that a high fertiliser effect could be achieved by applying the liquid fertiliser fraction, which is high in N and S, to growing crops (winter cereals). With separated digested fertiliser from decanter centrifuges, a slightly lower fertiliser effect was obtained on winter cereals, but still significantly better than unprocessed digested fertiliser. Today, fertilising growing crops is challenging when using both cattle slurry and digested biomass due to high ammonia loss. This can be significantly improved by using the liquid fertiliser.

However, the project did not succeed in achieving a sufficiently high concentration of nitrogen in the liquid sulphur-rich fraction from biofilters. The experiments showed a risk of high nitrous oxide emissions during application due to the large amount of liquid required to achieve a realistic nitrogen supply. Further technological development is needed to obtain a more concentrated liquid from biofilters, or alternatively, this liquid can be mixed with other fertiliser fractions.

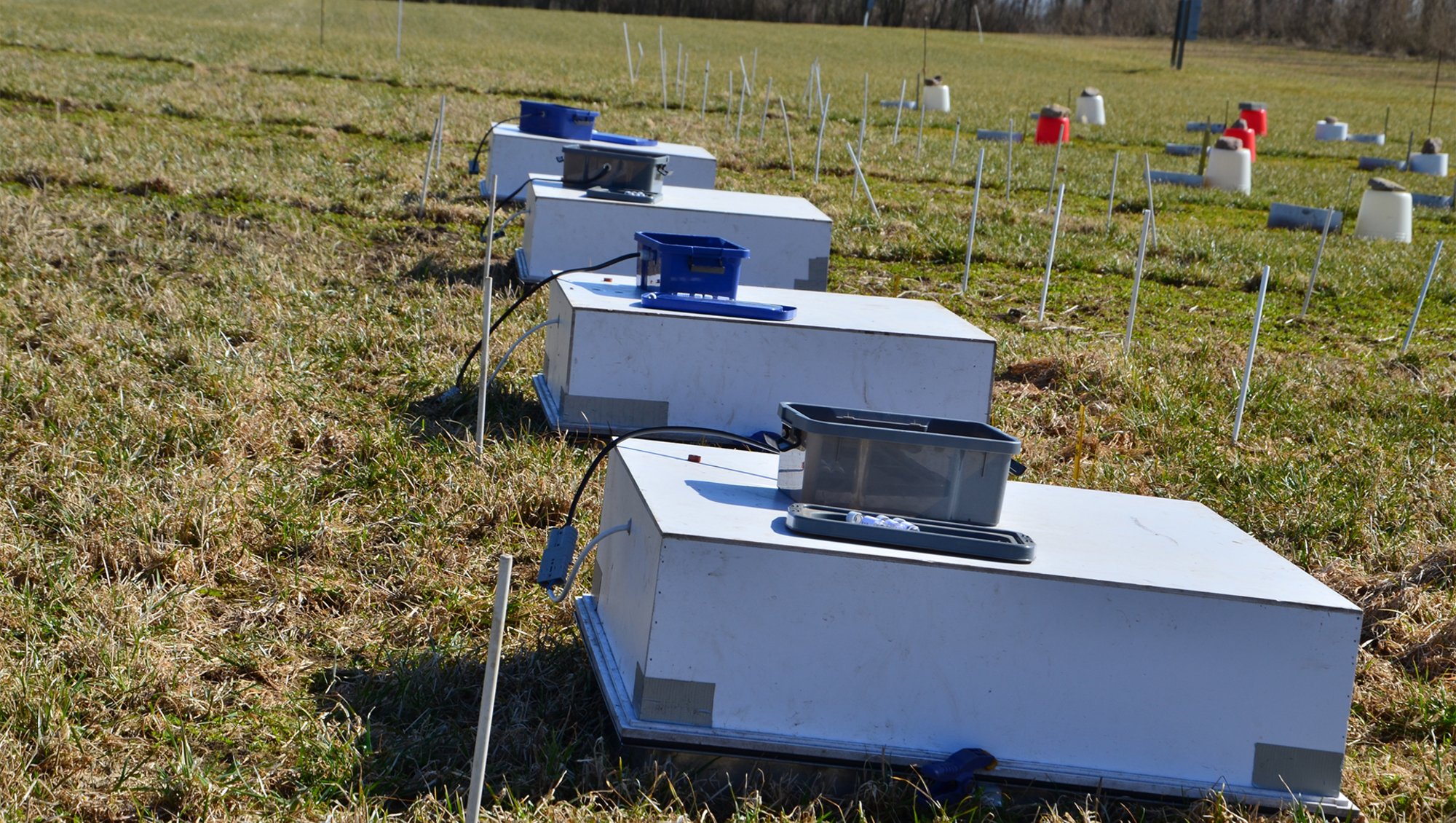

High fertiliser value by injecting fertiliser after ploughing (slurry placement)

Field trials with spring barley conducted in the project showed significant yield increases and very high nitrogen utilisation by injecting cattle slurry and digested fertiliser after ploughing, rather than the traditional injection before ploughing. Such a practice requires specialised injection equipment that can operate on the treated soil. The trials also found very high yield increases by increasing the injection of slurry from 100 to 200 kg total N/ha. This suggests that there is potential for higher organic yields, which can also reduce greenhouse gas emissions per produced unit.

The significance of the results – Implementation in practice

The project's results confirm that biogas treatment is an important tool to reduce greenhouse gas emissions in systems using organic fertilisers. The utilisation of fertilisers from biogas plants can be further improved by post-processing the digested biomass through separation, especially when applied to winter cereals. Demand from the agricultural sector for the new fertilisers would stimulate production.

Post-processing could further increase nitrogen utilisation. However, findings in the project indicate that further technical development is needed to achieve a more concentrated nitrogen fertiliser based on sulphur-rich liquid from biofilters. This could potentially make it more attractive to use in practice by reducing costs for storage and transport of large amounts of liquid.

Financial calculations show that the increased nitrogen utilisation through digestion and post-processing alone cannot cover the increased costs associated with this process. Therefore, the implementation of the tested system is likely to be realised only when the climate effect can be financially rewarded, making the more efficient fertilisers financially more attractive.

Project manager

Peter Sørensen

Aarhus University, Department of Agroecology

Tlf. 87157738

ps@agro.au.dk