How to make the best choice for careful, minimal and mild processing methods

A set of strategies and tools that helps organic food processors to select the most sustainable and gentle technologies for organic food processing is being developed in the ProOrg project. Now the tools have to be tested in practice, and the project are thus looking for food processing companies interested in finding more sustainable alternatives to current technologies used and in optimizing current processes.

By: Research assistant Caroline Modin Christensen (cmc@food.ku.dk) and Professor Lilia Ahrné (lilia@food.ku.dk), University of Copenhagen

Today there is a lack of mandatory standards and indications for organic food processing within the EU. ProOrg will develop a set of strategies and tools (Code of Practice) that can help organic food processors in the selection of appropriate technologies and innovations in line with the organic principles. It will give food processors guidance for making the best choice for careful, minimal and mild processing methods while addressing the organic principles (high food quality and low environmental impact).

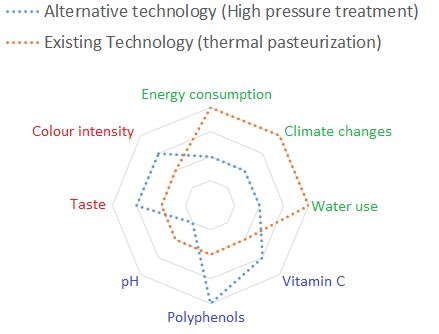

The main activity of ProOrg is to develop a practical and flexible Code of Practice for processors of organic food. The practicability of the Code of Practice is going to be tested in case studies with Danish food processors. Food processors that are interested in looking into their processing methods will have the opportunity to compare the performance of current processing technologies with alternative processing technologies. Food processors will be given tools that makes it possible to evaluate criteria in terms of sensory quality, nutritional quality and environmental impact. The figure below gives an example of two types of processing technologies for production of apple juice: High pressure treatment (Alternative technology) versus conventional thermal pasteurization (Existing technology). These two different processing methods are evaluated based on how the technologies affect a number of criteria within sensory quality, nutritional quality and environmental impact and the existing and alternative technology can be benchmarked by performing calculations.

Interested in optimizing your processes?

So far, the first draft of the Code of Practice has been developed and is now ready to be tested by food processors. We are recruiting companies to participate in the case studies. The case studies have been adapted to the current situation with the Covid-19 outbreak and will held online. In case you are interested in participating in the case studies, please contact us - see mailaddress above.

The tools that ProOrg offer can be adapted to all types of organic processes and products. The project will contribute to development of sustainable processed products through the support of the Code of Practice for organic processing. In addition, ProOrg will allow further improvement of organic food processing and will support the development of new production methods, which comply with the organic principles of guaranteeing consumers high quality, natural and sustainable food products.

For production of apple juice two types of processes can be compared. In the diagram, conventional thermal pasteurization (Existing technology) is compared with high pressure treatment (Alternative technology). The diagram shows how these two technologies affect a number of criteria (nutritional and sensory quality of the product as well as environmental impact during production of the product).

The ProOrg project is part of CORE Organic Cofund, which is coordinated by ICROFS See more at the project homepage.