ClimOptic

ClimOptic

- New climate-efficient fertiliser for organic plant production

There is a great need to reduce climate gas emissions from agriculture as part of the global goal of keeping man-made climate changes below 2 ° C. This requires both reduction of climate gas such as N2O from the field and increased carbon storage in the soil.

The climate profile from organic crops can be increased in two ways; either by reducing emissions per cultivated area or by increasing the yields. An effective reduction requires both ways to be exploited.

Research has shown that yields can be increased through better fertilisation, especially through organic fertilisers with increased nitrogen utilization. Other research has shown that the carbon content of the soil is increased primarily through increased supply of plant residues in crops and after crops, where, however, there is an interaction with high emissions of Nitrogen oxide from plant residues in the soil.

Purpose of the project

The purpose of the Organic RDD 4-project ClimOptic is to develop, document and demonstrate optimised organic slurry applied in interaction with changes in crop rotation and slurry management for more climate efficient organic plant production.

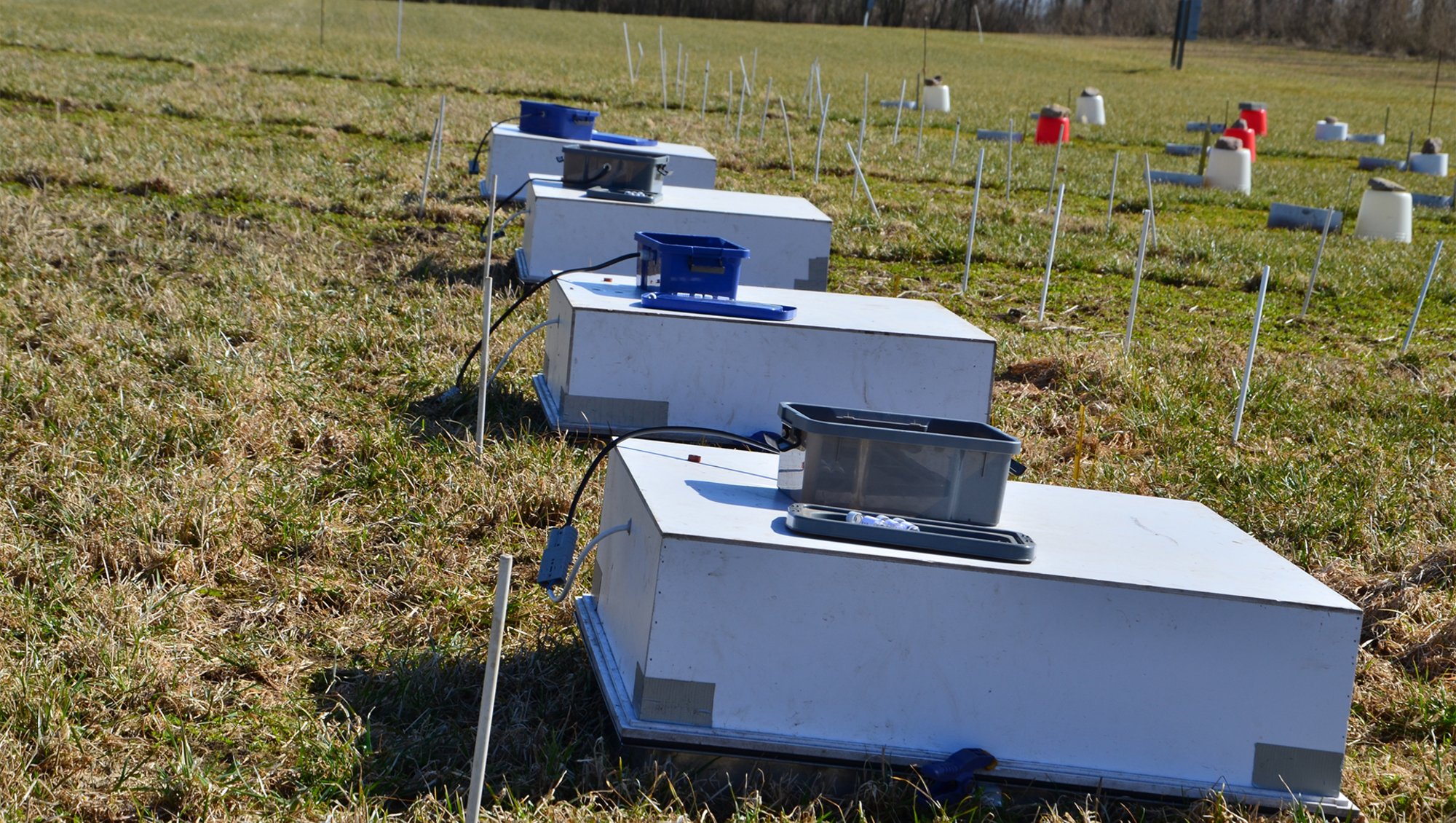

The project will specifically develop two new types of slurry based on bio-degassed manure and plant residues: 1) A liquid sulphate slurry plentiful in ammonium and sulphur, and 2) a dry pelletized phosphorus organic slurry. These fertilisers are expected to be utilised significantly more targeted in organic production than current slurry, with lower Nitrogen oxide emissions and increased carbon storage, while increasing yields.

ClimOptic is focusing on farms with poultry and pigs or pure plant production, where livestock manure and plant residues are converted into biogas plants in order to achieve high utilization of nutrients and minimize greenhouse gas emissions.

A number of methods are being tested to post-treat degassed biomass to produce organic fertilisers that can be better assigned to the crops at times when the plants best utilize the nutrients.

The finishing is done at the biogas plant using mechanical and biological methods that are compatible with the ecological principles.

The subsequent processing takes place at the biogas facility using mechanical and biological methods that are compatible with the organic principles.

The project is expected to result in a reduction of greenhouse gas emissions from organic farming of 97,200 tonnes of CO2 eq. The project is expected to provide the basis for increased yields of DKK 132 million and sales of climate-optimised fertilisers to a value of DKK 13 million annually.

Project period: 2019-2022

Project manager

Peter Sørensen

Aarhus University, Department of Agroecology

Tlf. 87157738

ps@agro.au.dk